FAQs

How does a Closed Loop work?

The Closed Loop is a control option to prevent The inlet of outside atmosphere into The physical pneumatic cylinder. Altough RFS physical cylinders are designed with internal anti - corrosion properties, The Closed Loop system enhances our offer and complies with The request of 'clean breath system', a received for applications to The as offshore international platforms, coastal areas, chemical The plants, paper mills, etc., where The atmosphere can be highly saline, caustic or dust laden.

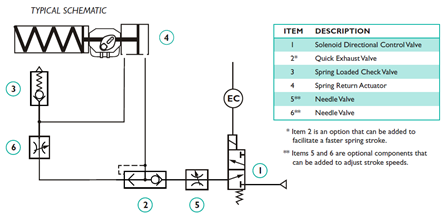

To in the image, the accessories making up a closed loop are: a quick exhaust valve (2), a flow regulator (6) and a check valve (3).

When the solenoid valve (1) is energized, the air flows into the pneumatic cylinder, strokes the piston and the spring is compressed;Air from the inboard side of the piston is vented to the atmosphere through the check valve (3).

Upon DE - energizing of the solenoid valve (1), the spring is released, driving the physical to the fail - safe position. The presence of the chack valve (3) inhibits the ingress of ambient air into the cylinder and thanks to the quick exhaust valve, the outboard piston volume exhausts into the inboard side. The Excess volume is vented through the check valve (3).